Here we look at the five basic stages of an automation project:

Stage 1 – Identify.

Stage 2 – Develop & Finance.

Stage 3 – Build.

Stage 4 – Commission.

Stage 5 – Run & monitor.

As the Project Leader for a manufacturing facility, I get to come up with and implement all sorts of projects – Lean, Excellence, Quality, Asset Replacement etc. The one type of project I have always had problems with is Automation.

I’m not talking about Industry 4.0, the integrated manufacturing revolution that I read about and get rather excited by the seemingly endless possibilities. No. Just plain and simple Automation –

“The technology by which a process or procedure is performed without human assistance”

The reason for my troubles is that our products, whilst being technically advanced and world leading, are a niche product. This results in a product base that is wide and an average batch size of 100 – and there lies the problem, with such small batch sizes it is impossible to get an automation project proposal past the bean counters!

Stage 1 – Identify.

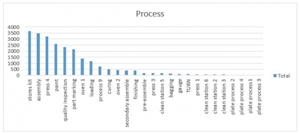

So, with such a wide product base, how on earth could I identify a product that we could take through an automation development project?

DATA – simple right? Whenever anybody says “collect data” what they fail to mention is that you need to identify what data you need to collect and analyse! Where you have fully integrated IT systems it’s pretty easy! When this is one of your first projects or you have simple data to deal with you have to think logically and stick to the basics (or what your data gives you)

The basics every company should have is:

- What have you bought

- What have you made

- What have you sold

Pull off the data for each three over the last 12 months, into a spreadsheet and sort by quantities!

Now with this data you should be able to identify those products that you can focus your attention on and in some cases you may be able to automate the whole process for one product or identify a common process for several products.

I selected 11 components that would go through a similar pressing operation and calculated that if I could reduce this cycle time from 45sec on the current press to 25sec on a new press with automation then I could save about £24k/yr. – that’s some good figures to start with, but won’t be enough to get a 3 year payback for the bean counters.

Stage 2 – Develop & Finance

Ok, so we have identified a potential project, we have some idea of how much we could save but it’s probably not enough! Time to get the professionals involved.

I discovered quite early on that we design and make widgets, in fact we make great widgets! What we don’t do is design and build automation equipment. I don’t have teams of electrical, software and mechanical engineers to call upon and dedicate 100’s of hours to creating my new machine.

There are, however, many companies out there that specialise in such activities, have a good look around, do some research and take some advice, try and identify between 3 & 5 companies that could assist you.

Invite them in, explain what you want to do, go through the parameters, define “what good looks like” etc. Then send them away to supply a quote, when they ask what the budget is, you obviously have an idea but this is going to be dependent on the functionality of the equipment that gets provided, so be vague i.e. “I would like it to come under £100k but if you can exceed these parameters (throughput time, or including a vision system to check components etc.) I could potentially look at more so please feel to free to add these on as options.

This is a really important part of the process, allowing the experts a bit of free reign to be innovative, obviously you don’t want a machine that can produce parts as per your brief but costs £750k because it has a super fancy lighting system to rival a rock concert, so keep in contact with them over the following weeks to help guide them.

In a few weeks you should receive a few quotes.

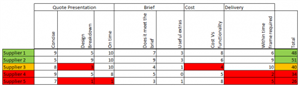

Score and compare them on the following: (Feel free to add as many as you like)

- Presentation of Quote – Is it concise? Does it give a breakdown of the design (I wouldn’t expect a drawing but a general list of equipment/functions)? Was it in on time?

- Brief – Does it meet the brief? If not, how close? Any extra functions/options?

- Cost – How much vs functionality i.e. if it’s £10k over budget but can produce twice as much then it is great!! WARNING – something that looks too good to be true generally is, be careful the company is not buying your job as they will favour other work over yours, they’ll cut corners or worse, go under (yes that has happened to me with £60k invested so do some background checks too!)

- Delivery – When do you need it?

You may need to clarify a few things with each supplier as you go through this process.

Once you have completed the comparison you should have whittled it down to two or three (or decided you may need to start again).

Now you should go and visit them, spend a few hours with them, chat to people, view current projects etc. get a feeling for the sort of company they are, their competencies and where your project sits in their portfolio – Right at the top and they may not have the expertise to carry it through, at the bottom and they may see you as small fry.

Now pick one – don’t procrastinate, just do it!!

So once I had gone through this process I chose an Automation company, which we shall call ABC Automation (not the real name), which provided a quote just slightly over budget at £90k with a machine cycle time of 15s, which equates to yearly savings of £36k – now that gives a 2.5 year payback. The bean counters should go for that!

Time to write your Capex proposal, compile a presentation, chat to your boss or whatever your companies’ process is.

Stage 3 – Build

You have just received the news that your Capex has been approved – GREAT!!!

Now what?

Time to double check each bit of the proposal, each bit of information that has been used (drawings, emails, discussions etc.), visit the supplier once more and talk through the requirements, ensure the lead time is still accurate and they understand what is required. Raise a purchase order.

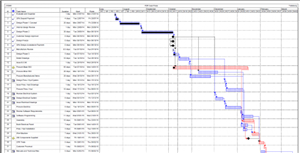

As soon as you have sent the PO you should call your contact at the company and request a project plan that you both can follow.

ABC Automation gave me a great project plan; detailed and concise. And at first they followed it.

Design drawings came through when they should, project meetings occurred when they should – Great! If the whole project went like that it would have been a doddle!

I visited a few times during the design phase to discuss requirements, when the drawings came through they were easy to sign off as I recognised them and needed little clarification.

I then left them to manufacture / order the components and start the build process. All was going well, or so I thought. We kept in contact as the components started to come in and I had regular updates of the progress on the project plan.

At 30% completion, as per the project plan, I organised a visit with them, they seemed a little apprehensive on the phone….. I soon established that they were way behind!!!!

They hadn’t ordered half the components, there were several different copies of drawings strewn around the incorrectly manufactured base plate and the full design was incomplete – DISASTER!

When disaster strikes you must take hold of the situation, although you may want to run away and bury your head, work with them to solve the problems – Create a partnership with them, I do this with every project now, it really helps to be a part of the team.

I was visiting them one day a week; redesigning, fitting and managing the build of my machine.

I don’t get involved like this every time, and neither should you! But visiting regularly and keeping the project on brief is necessary.

Once the machine is built you will need to test it thoroughly, it will be much easier to make adjustments, or even add/remove functionality whilst it is in the workshop.

This is known as a Factory Acceptance Test or FAT for short.

It is always a good idea to run production parts through the machine as it would run onsite, test failure mechanisms by introducing know faults (below quality parts, blockages etc.) and test the safety circuit thoroughly (interlocks, light curtains etc.) DO NOT put yourself in harms’ way to do this.

Review all documentation prior to signing off the machine.

If there are any issues, discrepancies or faults, work with your automation partner to overcome them prior to signing off.

Whilst I was going through the FAT test the salesman at ABC Automation tried discussing all the “extra work” that they have put in and how much extra this has cost them.

This should not be entertained at all at this point! Ask them to summarise the extras with a full breakdown of costs that you can both discuss at a more suitable time.

I didn’t follow this rule however, I suggested that as it was a year late, if I was to consider paying them extra they would have to consider paying me the £36k in lost revenue. A much harder line than I would normally take but after managing the project for them for the last year I wasn’t going to entertain paying them a penny more! It had the desired effect.

Stage 4 – Commission

Great, the machine is ready! Are you?

Whilst all this has been going on you should’ve have been making plans:

Where is it going?

Can you get it there?

Will it need breaking down to get there? If so; does your Automation partner know?

Infrastructure requirements? (Elec, water, air…)

Once these are all in place and you have a delivery/installation plan you can look forward to the arrival.

Once the machine has arrived, been sited and setup by your automation partner you will need to go through a few things, which MUST include: Risk Assessments, writing SOP’s and formal Training of personnel and may include setting up PPM, training maintenance personnel, assigning asset numbers etc.

When the formalities have been completed you should run the same trials that you completed at the end of stage 3. Any discrepancies in the results should be investigated and rectified.

Remember; Repeatability is what will make your automation project a success, a process that is out of control will sink it!!

Following this, a few full production batches would be a good idea before handing over to production, so that you know that it has been tested thoroughly – any problems should be rectified prior to handover.

With all the problems I had had with ABC Automation, I was dreading this! It turns out though they were very good at this end of the project.

Communication was excellent, all plans went through as per timing plan, and the engineer was here for a whole week, even though he was just watching it for the last couple of days.

Stage 5 – Run & monitor

Once the equipment is in and running you should monitor the process.

Are you getting the correct number of components?

Are they coming off at the speeds required?

Are they correct?

What is the scrap level? And is this permissible?

Is it functioning as per brief? Or do you need to call in the engineers to adapt/modify?

How are the PPM jobs progressing? Any early failures or excessive wear patterns?

How are the production personnel adapting to the new process? Do they need more training?

You can start to build up a history of the machine very quickly which can give you an indication of future problems before they occur.

You can also monitor the performance of the equipment via KPI’s and feed these back to management and, where appropriate, employees.

Once up and running, we managed to increase productivity threefold! I hadn’t taken into account that automating this part of the process changed the way that the whole line operated. We very quickly became a leaner operation. This meant that the payback was around 18 months!

And, more importantly, we were able to keep up with our customers’ demands!