Hi Guys. Not been on for a long time, just had a bit of a search and couldn't really find anything so thought i would ask and see what you all thought.

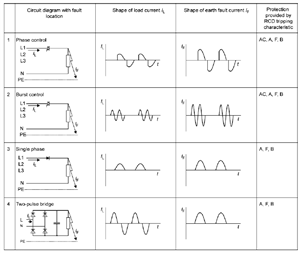

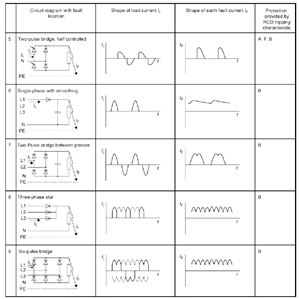

1. Are we or will we be coding type AC rcd's if there are LED's or induction hobs, lots of electronics etc present.

2. How much DC leakage does it actually take to saturate an rcd and cause problem?

3. How much does a standard LED lamp or induction hob leak ?

If we test an AC RCD with no load and it's fine then re-test it with all LED lights, induction hobs etc turned on and it operates correctly could we then say that it is ok with a note on EICR OR EIC if installing any of the above.

Obviously also on an EICR if the RCD then doesn't operate with it all on it becomes a C2 ?

Any thoughts

Gary