davezawadi:

There is a serious problem with the standards making process, and that is that interactions between various ones from differing sources lead to foolish and unnecessary outcomes. The most obvious one is electric cars (chargers) not being class 2 because someone didn't see that they could not safely be earthed in the external environment, which we all know and have a lot of regulations to reduce risks to presumably acceptable levels. However street furniture using PME is considered entirely satisfactory and does not cause a significant number of accidents. We need to be consistent on the basis of real risk only, not on "what if" scenarios.

Bob C:

Gentlemen, I think we have drifted from my initial query. My question was about the internal power strip (generally 13amp) which arrives pre-fitted within the Data Rack. Is this classed as Equipment or is it part of the fixed wiring? The Client through his advisers consider it to be part of the fixed wiring and therefore should have RCD protection as they are unwilling to complete a risk assessment. Their initial thought was to fit an isolator above the rack negating the need for RCD protection and negating the need for them to produce a risk assessment, however they have now been advised that the power strip inside the cabinet requires an RCD or Risk assessment. Feedback from other bodies like Select advise that the power strip is not part of the fixed wiring and it does not come under the EICR therefore an RCD is not needed if you use an isolator rather than an external Commando socket, however if the Contractor fits the power strip after delivery of the rack it becomes part of the fixed wiring. I would appreciate comments on this point.

In the UK, the consensus seems to be that general-purpose socket-outlets (BS 1363-2 and BS EN 60309-2) are exactly that ... general purpose, unless you have them locked away somewhere that's only accessible to suitably competent persons, for example ... hence the risk assessment requirement.

AJJewsbury:

In the UK, the consensus seems to be that general-purpose socket-outlets (BS 1363-2 and BS EN 60309-2) are exactly that ... general purpose, unless you have them locked away somewhere that's only accessible to suitably competent persons, for example ... hence the risk assessment requirement.

Same thinking for 60320 sockets? (C13 and C19s?) - pretty common in rack PDUs.

- Andy.

They are not socket-outlets no matter how common.

Are you advocating that RCDs are required for couplers now, as well as socket-outlets, and perhaps that the requirement should also be extended to connection units and connecting points too?

AJJewsbury:

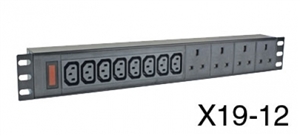

No, not the couplers (e.g. on the end of a flex) - I mean the "chassis mount" outlets - often incorporated into rack mounted power distribution units (PDUs) in just the same way that BS 1363 outlets are. One example:

- Andy.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site