Hi I have a three phase motor that I wish to run from a single phase supply.

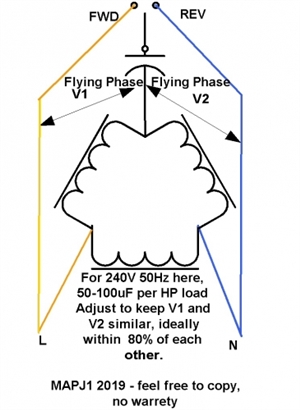

Does anyone know what the formula is for working out the correct capacitance.

Thank you

Daniel

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site