Looking for a bit of clarification on disconnection times here. I have information on an ABB Mccb that has been listed as failing on maz zs.

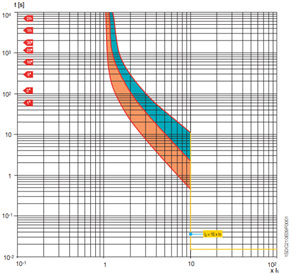

The max zs referenced for the unit is 0.07 ( 250a TMD TP set at maximum) the measured zs is 0.08, however, the max Zs is listed for 0.4 and 5 seconds.

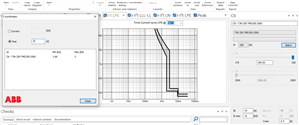

Looking at the time current curve on the mccb once you hit 3.5.times 250a you are in the thermal tripping zone of the mccb. Using the curves software from ABB it indicates a 5 second disconnection can be achieved with 1.66ka.

How do I work this out? is the MaxZs listed as the same for both disconnection times because the only way to ensure a 5sec disconnection is to have an instantaneous trip?